Adhitz 728

Adhitz

Sunday, January 2, 2011

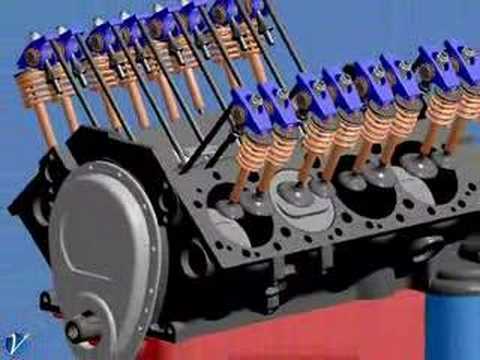

3D animation of a fuel injected V8

The Mazda Rotary Engine Part 1

How Rotary Engines Work

How Rotary Engines Work

See more car engine pictures.

In a piston engine, the same volume of space (the cylinder) alternately does four different jobs -- intake, compression, combustion and exhaust. A rotary engine does these same four jobs, but each one happens in its own part of the housing. It's kind of like having a dedicated cylinder for each of the four jobs, with the piston moving continually from one to the next.

The rotary engine (originally conceived and developed by Dr. Felix Wankel) is sometimes called a Wankel engine, or Wankel rotary engine.

In this article, we'll learn how a rotary engine works. Let's start with the basic principles at work.

The rotor and housing of a rotary engine from a Mazda RX-7: These parts replace the pistons, cylinders, valves, connecting rods and camshafts found in piston engines.

In a rotary engine, the pressure of combustion is contained in a chamber formed by part of the housing and sealed in by one face of the triangular rotor, which is what the engine uses instead of pistons.

The rotor follows a path that looks like something you'd create with a Spirograph. This path keeps each of the three peaks of the rotor in contact with the housing, creating three separate volumes of gas. As the rotor moves around the chamber, each of the three volumes of gas alternately expands and contracts. It is this expansion and contraction that draws air and fuel into the engine, compresses it and makes useful power as the gases expand, and then expels the exhaust.

We'll be taking a look inside a rotary engine to check out the parts, but first let's take a look at a new model car with an all-new rotary engine.

ign="right" cellpadding="3" cellspacing="0" width="200">

http://www.howstuffworks.com

The Mazda Rotary Engine Part 2

How Rotary Engines Work

How Rotary Engines WorkIn a piston engine, the same volume of space (the cylinder) alternately does four different jobs -- intake, compression, combustion and exhaust. A rotary engine does these same four jobs, but each one happens in its own part of the housing. It's kind of like having a dedicated cylinder for each of the four jobs, with the piston moving continually from one to the next.

The rotary engine (originally conceived and developed by Dr. Felix Wankel) is sometimes called a Wankel engine, or Wankel rotary engine.

In this article, we'll learn how a rotary engine works. Let's start with the basic principles at work.

The rotor and housing of a rotary engine from a Mazda RX-7: These parts replace the pistons, cylinders, valves, connecting rods and camshafts found in piston engines.

In a rotary engine, the pressure of combustion is contained in a chamber formed by part of the housing and sealed in by one face of the triangular rotor, which is what the engine uses instead of pistons.

The rotor follows a path that looks like something you'd create with a Spirograph. This path keeps each of the three peaks of the rotor in contact with the housing, creating three separate volumes of gas. As the rotor moves around the chamber, each of the three volumes of gas alternately expands and contracts. It is this expansion and contraction that draws air and fuel into the engine, compresses it and makes useful power as the gases expand, and then expels the exhaust.

We'll be taking a look inside a rotary engine to check out the parts, but first let's take a look at a new model car with an all-new rotary engine.

|

Mazda has been a pioneer in developing production cars that use rotary engines. The RX-7, which went on sale in 1978, was probably the most successful rotary-engine-powered car. But it was preceded by a series of rotary-engine cars, trucks and even buses, starting with the 1967 Cosmo Sport. The last year the RX-7 was sold in the United States was 1995, but the rotary engine is set to make a comeback in the near future.

The Mazda RX-8 , a new car from Mazda, has a new, award winning rotary engine called the RENESIS. Named International Engine of the Year 2003, this naturally aspirated two-rotor engine will produce about 250 horsepower. For more information, visit Mazda's RX-8 Web site.

Rotor

The rotor has three convex faces, each of which acts like a piston. Each face of the rotor has a pocket in it, which increases the displacement of the engine, allowing more space for air/fuel mixture.

At the apex of each face is a metal blade that forms a seal to the outside of the combustion chamber. There are also metal rings on each side of the rotor that seal to the sides of the combustion chamber.

The rotor has a set of internal gear teeth cut into the center of one side. These teeth mate with a gear that is fixed to the housing. This gear mating determines the path and direction the rotor takes through the housing.

The housing is roughly oval in shape (it's actually an epitrochoid -- check out this Java demonstration of how the shape is derived). The shape of the combustion chamber is designed so that the three tips of the rotor will always stay in contact with the wall of the chamber, forming three sealed volumes of gas.

Each part of the housing is dedicated to one part of the combustion process. The four sections are:

- Intake

- Compression

- Combustion

- Exhaust

The output shaft

(Note the eccentric lobes.)

http://www.howstuffworks.com

Air Car Water Car Fuel Clean Motor Save Gas Best Engine

The Compressed Air Car developed by Motor Development International . The company ended all such speculations on Tuesday stating that the compressed air car engine . Airliner Ditching In Surf Video · Live Ants In The Brain Hoax .

25 Feb 2008 . Guy Negre of MDI's Air Car engine that runs on compressed air. . There are many more 2008 New York Auto Show videos with MDI's OneCAT at: .

http://www.google.com.mx/search?hl=fr&q=video+compressed+air+car&btnG=Recherche+ . The compressed air is let into the engine, expanded in a decompression .

You can see the results on video clicking on the following link: . According to the LEI the compressed air engine offers numerous advantages: .

"I am amazed by this concept of a compressed air driven car. What about a regenerative . .. Notice you never saw a video of the engine actually working. .

Air Car (1 of 2) from France. cplai 241 videos. Subscribe . . Added to queue Horizontal 4-stroke Compressed Air Engineby cffellows97803 .

You heard me right, an air engine. An engine that uses compressed air to . They have a good range and the MDI Air-Car has an on board air compressor . Sesame Street Clips Video Showcase: Can you tell me how to get to Sesame Street? .

Air4zero compressed air motors technologies converting cars, bikes, boats, . The best part is that the converted engine runs at almost zero cost and zero . air fuel that would save close to $5000 dollars on gas cost. annually per car! . Working model on video will be ready soon! Waste-Air Power Plant (W APP) .

10 Aug 2008 . Click here to see original video.The OneCAT Air Car will be at the New York . Guy Neg re of MDI Air Car engine that runs on compressed air.

Air Car by Guy Negre on Beyond Tomorrow video from YouTube. Guy Negre of MDI Air Car engine that runs on compressed air. Emissions are only filtered air .

3 Nov 2009 . Reciprocating engines all work on compressed air. . . Nissan's new concept car 'feels like flying' (w/ Video) created .

This five-seater car runs on compressed air, has zero pollution, very low running costs and will cost about . Never miss a Flixxy video. Become a Fan: .

4 Oct 2004 . The Air Car's pistons, pumped by the escaping compressed air, can take the . guzzlers and chose engine capacities reflecting their real needs, he said, . Video. Protecting endangered manatees from tourists. Video .

Compressed air car. In this video you can see the car being driven and hear . Compressed air engines have a way to go, and they will probably one day have .

8 Nov 2008 . Below are three YouTube videos that showcase and describe the AirPod. . I think the compressed air engine's place is as part of a hybrid .

7 Sep 2008 . Also watch more autos, motorcycles & planes how to videos . intake system that controls the amount of air flowing into the car's engine. .

The Air Car is real, videos on at http://www.youtube.com/user/CATvolution. Guy Negre of MDI Air Car engine that runs on compressed air. .

25 Sep 2010 . This video will show you how to correctly change your car air . Air is the one thing that your engine needs more than fuel but . Connect the air hose to the compressor and use the compressed air to blow out the dust. .

30 Sep 2008 . The Magnetic Air Car supposedly uses the same compressed air technology as the Tata air car initially, but differs when it gets to the actual engine. . The air turbocharer you show in your video has been around almost .

23 Jul 2007 . By putting a windmill on the car you are just converting the energy that the compressed air engine made to move the car forward back to .

29 Apr 2009 . I made an engine out of legos that runs on compressed air. It's slow but has high torque. . Lego Pneumatic (Air Powered) Car 2 (flv video) .

8 Aug 2008 . The compressed air car planned for the U.S. market would be a . Video Watch what a prototype looks like and why the cars may take off in cities » . Whether the engine uses just air or both air and fuel would depend .

Guy Negre of MDI Air Car engine that runs on compressed air technology. . . fizzguts . 2009 Geneva Motor Show: MDI Compressed Air Car - Exclusive Video . .

24 Nov 2008 . MDI's Mini FlowAir compressed air-powered car . Click PLAY to watch a video about Angelo's engine and vehicles .

How To Convert Your Car To The Air Engine. Learn About The Concept Of Powering Your Car With Compressed Air Instead Of Combustible Fuel While Exploring 15 .

22 May 2009 . I watched the MDI video that I included in my last air car post again, . Keep in mind, however, that using compressed air to power a car involves . the compressed air to increase the fuel efficiency of your engine. .

This site may harm your computer.

Compressed Air Engine animation video from YouTube. A quick 3ds max .

27 Feb 2008 . The car will be driven by compressed air stored in carbon-fibre tanks. . . air powered engine is runnning !! Another site with videos : .

6 Mar 2009 . But the cheap, environmentally-neutral compressed air engine also lends itself . . Thanks tgmeob - yes, I've seen the video but didn't post it as it was . Zero Pollution compressed Air Car set for U.S. launch in 2010 .

Related videos. More in Others - Auto · Learn about Car Engine Air Induction . The compressed air pushes the pistons in the engine up and down rather than .

5 Aug 2003 . See a short video of it running at http://www.cafecengine.com . . Wouldn't a air compressed car hybrid with an electric engine provide the .

Compressed air in a can or tank can help car washers get loose dirt from . Learn about compressed air from a car wash owner in this free video on professional. . How to Top Off Your Car Wash · Engine Compression Specifications .

13 Aug 2010 . Guy Negre of MDI Air Car engine that runs on compressed air . I've heard 60-70 mph but would love to see a video of it moving that fast. .

2 Aug 2010 . Guy Negre of MDI Air Car engine that runs on compressed air . . I've heard 60- 70 mph but would love to see a video of it moving that fast. .

29 May 2007 . This innovative Air car "is powered by compressed air, stored in a carbon-fiber tank at 30 MPa (4500 psi)." Video after the break. .

Air Car (2 of 2) from Australia 3.45 min. | 4.8233333 user rating | 373118 views . A rotary engine runs on compressed air. Part 2 of 2. .

19 May 2009 . 2009 Geneva (Switzerland) Motor Show: MDI Compressed Air Car - Exclusive Video. . I saw this video that it is here on the archives the air .

EABS Insight of an air car engine video from YouTube. air car engine. . Compressed Air Cars - France This car can run 200km without polluting the .

8 Jan 2008 . Look after the jump for a video on how the engine works. . anyhow… this air powered engine car is not a bad idea… it is a good thing to .

12 Dec 2010 . The MDI Air Car is a Compressed Air Vehicle with a low price tag, . The MiniCat, running only on a compressed air engine, . Nissal Releases "How It's Made" Video for Leaf Posted on Wed, 12/08/2010 - 16:23 .

2 posts - 2 authors - Last post: 3 Nov 2008The CAV will use compressed air to move the cylinders of the car's engine the same way the explosion in a traditional gasoline engine does. .

10 posts - 7 authors - Last post: 29 MayVideo A compressed air engine Car Videos. . Here is a video of a compressed air engine I made from scratch. Inventor1 AZ. Attached Files .

21 Feb 2008 . The six pistons in the Air Car's engine are pushed by compressed air rather than gasoline combustion, an idea developed by F1 race car .

STIRLING ENGINE TAKING ONE APART HOT AIR ENGINE Solar Powered Sun Generator Motor

The Stirling Engine (or hot air engine) Explained

1820, when steam engines operated everywhere, Robert Stirling, a Scottish vicar, and his brother James built a new engine. They used an outside burn, additionally hot air was sufficient for the operation of the engine. This principle has theoretically already been developed by the English flight pioneer Sir George Kayley twenty years earlier.

1820, when steam engines operated everywhere, Robert Stirling, a Scottish vicar, and his brother James built a new engine. They used an outside burn, additionally hot air was sufficient for the operation of the engine. This principle has theoretically already been developed by the English flight pioneer Sir George Kayley twenty years earlier.Stirling proceeds from the fundamental characteristic of air that it needs more space with rising temperature. If the volume remains constant, the pressure rises. All thermal engines work because of this characteristic. The basic principle of the Stirling engine is described in the following.

Mode of operation of the Stirling engine A machine, whose cylinder is alternating cooled and heated up again, would work, too. But for the change of temperature of the cylinder large energy quantities would be wasted. Stirling developed therefore a new principle: He uses two cylinders and two pistons: a working and a displace piston. The cylinder left is constantly heated up on the top while it is cooled at the lower part. The displace piston left seals not, it is of a porous structure, which lets air pass through. If the displace piston is now in the lower dead-center, air is strongly heated up and the pressure push on the working piston on the right, which slides to the right now. The left piston gets now pulled upward by the coupling of the two pistons. Air is strongly cooled, and together with compression work from the flywheel the working piston is brought again to the left, the displace piston slides down and the air is heated up again.

Mode of operation of the Stirling engine A machine, whose cylinder is alternating cooled and heated up again, would work, too. But for the change of temperature of the cylinder large energy quantities would be wasted. Stirling developed therefore a new principle: He uses two cylinders and two pistons: a working and a displace piston. The cylinder left is constantly heated up on the top while it is cooled at the lower part. The displace piston left seals not, it is of a porous structure, which lets air pass through. If the displace piston is now in the lower dead-center, air is strongly heated up and the pressure push on the working piston on the right, which slides to the right now. The left piston gets now pulled upward by the coupling of the two pistons. Air is strongly cooled, and together with compression work from the flywheel the working piston is brought again to the left, the displace piston slides down and the air is heated up again.Robert Stirling called the displace piston also re-generator. In the upper animation only a sponge like piston is used, but in other constructions e.g. a close wire mesh is used as piston. This re-generator can, like the name already says, “regenerate” the air. If the piston goes upward, it is flowed through by warm air and takes up a part of the energy of the air then - it stores it. If the piston goes downward, it is flowed through by cold air now and delivers its stored energy to it. At the same time the wire mesh cools down. The piston helps so to avoid losses of energy. Also because of the re-generator, Stirling engines reach excellent efficiencies.

Modern Stirling engines The Stirling engine appeared at the beginning as a good alternative to the steam engines, but the success was not so big because of high production costs (two cylinders) and the small performances compared with its size. In this century, when people began to think about the environment, the stirling engine could play out its strengths partially.

It convinces by very quiet running, an excellent efficiency and good exhaust quality, since the burn takes place outside of the cylinder. The company Phillips for example designed 1938 a Stirling engine, which operated with helium as working gas (conductivity better than in air). The Phillips engine was quite well sold and could be operated with solar energy. So it was used as mobile refrigerator, for the power supply of smaller devices as well as on satellites.

It convinces by very quiet running, an excellent efficiency and good exhaust quality, since the burn takes place outside of the cylinder. The company Phillips for example designed 1938 a Stirling engine, which operated with helium as working gas (conductivity better than in air). The Phillips engine was quite well sold and could be operated with solar energy. So it was used as mobile refrigerator, for the power supply of smaller devices as well as on satellites.The so-called ?-type stirling engine uses two pistons, which are around 90° out of phase in V-arrangement. The displace piston is missing, replaced by a fix installed re-generator. The ?-type Stirling engine functions because of the different lever lengths, with which the piston rods attack at the main shaft. For a closer explanation of this engine you can read the excellent description on the homepage of Peter Fete.

Future

FutureAlthough the stirling engine would have a large development potential, there won’t be a larger production soon. The relatively small performance compared with the size and the weight of the engine hardly permit a use in cars or airplanes. But as small mobile generators, stirling engines are a good choice. It enjoys a big popularity in the model construction, where small steam engines and stirling engines experience a real revival.

http://blog.vadaenergy.com

2 stroke outboard Vrs. 4 stroke outboard

Is There a Difference Between Two- and Four-Stroke Oil?

Two-stroke engines are more powerful and compact than the four-stroke, which is why they are found on the back of so many boats. But some boats do have four-stroke engines. When you purchase outboard motor oil, you’ll notice that there is both two- and four-stroke oil, but is there really any difference? As we all know, one of the biggest differences between the two types of motors is how you put oil in the system. In a two-stroke motor the gas and oil are mixed, while in a four-stroke the oil is contained in a separate compartment.

Two-stroke engines are more powerful and compact than the four-stroke, which is why they are found on the back of so many boats. But some boats do have four-stroke engines. When you purchase outboard motor oil, you’ll notice that there is both two- and four-stroke oil, but is there really any difference? As we all know, one of the biggest differences between the two types of motors is how you put oil in the system. In a two-stroke motor the gas and oil are mixed, while in a four-stroke the oil is contained in a separate compartment.

Two-stroke oil costs more, but is it really worth the extra money. The simple answer is yes. And the reason is that two-stroke motors are more susceptible to wear because of the immense amount of power they generate in half the movements. Two-stroke oils have higher ratings to ensure your engine gets the protection it need.

2- stroke engine

| Engineering >> How Things Work >> How 2-Stroke Engines Work |

| Introduction |

| If you have read How Car Engines Work and How Diesel Engines Work, then you are familiar with the two types of engines found in nearly every car and truck on the road today. Both gasoline and diesel automotive engines are classified as four-stroke reciprocating internal-combustion engines. There is a third type of engine, known as a two-stroke engine, that is commonly found in lower-power applications. Some of the devices that might have a two-stroke engine include:

|

| Two-stroke Basics |

This is what a two-stroke engine looks like:  You find two-stroke engines in such devices as chain saws and jet skis because two-stroke engines have three important advantages over four-stroke engines:

These advantages make two-stroke engines lighter, simpler and less expensive to manufacture. Two-stroke engines also have the potential to pack about twice the power into the same space because there are twice as many power strokes per revolution. The combination of light weight and twice the power gives two-stroke engines a great power-to-weight ratio compared to many four-stroke engine designs. You don't normally see two-stroke engines in cars, however. That's because two-stroke engines have a couple of significant disadvantages that will make more sense once we look at how it operates. |

2 Stroke & 4-Stroke Cycle Engines

Basic 4-stroke and 2-stroke engine operating cycle

4-stroke engine cycle consists of stroke Entry, compression stroke, power stroke and exhaust stroke

intake stroke

CASH movement of the piston to the KBS.

Inlet valve is open.

Ekzoz valve closed.

Air fuel mixture sucked.

Inlet valve is closed.

Ekzoz valve closed.

Air fuel mixture is compressed.

power stroke

Both valves are closed

Plug penyucuh produce fireworks

Fuel air mixture burns

Piston less strongly than the KBS CASH

ezkos stroke

The exhaust valve opens.

Inlet valve is closed.

The piston moves from the KBS to CASH.

Combustible gas that pushed out.

http://icetoolzer.blogspot.com

Car Engine Part by Part

Car Engine: Parts, Work, Problems. Part 1

Before to start working with the engine you should make sure that you have a proper manual. Online manual from ALLDATA is very good information material. The engine can be viewed as a heart of a vehicle which pumps air and fuel instead of blood. All engines are design to convert fuel and air into rotary motion in order to drive car’s wheels. How is this achieved?

Before to start working with the engine you should make sure that you have a proper manual. Online manual from ALLDATA is very good information material. The engine can be viewed as a heart of a vehicle which pumps air and fuel instead of blood. All engines are design to convert fuel and air into rotary motion in order to drive car’s wheels. How is this achieved?

Pistons. They move up and down in the cylinders. Most cars have four, six or eight pistons. The so called combustion chamber is placed in the upper side of the piston. Here the fuel and air are getting mixed before being ignited. Crankcase full of oil is situated on the other side of the piston. There are ring provided in pistons which prevent oil from getting into the combustion chamber and fuel and air from mixing with the oil. Pistons are made from lightweight aluminum and they are moving in the cylinders without touching their walls moving on a thin oil layer. In the event the rings are damage oil gets into the combustion chamber which results in grey smoke coming out of the exhaust. In this case the pistons can score the cylinder walls damaging the engine which leads to a serious repair.

Crankshaft. Through the connecting rod the crankshaft is connected to the pistons. As the piston is floating up and down in the cylinder it rotates the crankshaft thus converting straight line motion into rotary one.

Valvetrain. It consists of valves, arms, rocker, pushrods, lifters and cam shaft. The fuction f the valvetrain is similar to that of a traffic cop. It lets air and fuel in and out of the engine in a proper time. The camshaft being synchronized with the crankshaft by the chain or belt controls the timing.

These are the main parts of the engine and now you have an idea of their work. Now we are going to give you an idea of what is going on in the engine during its normal operation. Today most modern cars have four-stroke (four-cycle) engines. The cycle of their action consists of four distinct events. A complete cycle of four-stroke engine has two crankshaft revolutions. The 4-stroke cycle consists of the following events:

Intake stroke. The intake valve is opened by the camshaft and the piston is moving down the cylinder.

Compression stroke. The piston is moving back up the cylinder and makes the intake valve close. Thus the combustion chamber is sealed off. The fuel and air are getting mixed.

Power stroke. When the pistol is already near the cylinder top and the fuel is compressed this mixture is ignited with spark plug. The piston is pushed back down the cylinder by the explosion and the crankshaft is driven.

Exhaust stroke. When the piston is approaching the cylinder’s bottom, the exhaust valve opens and the gasses go out through the exhaust system.

So the four events mentioned above and taken together make a complete cycle. Are you sleeping now because you are tired of bare theory? We had to tell you all these boring things to give you a general idea of engine’s work. In the following part of the article we’ll talk about the real problems you can have with al the parts mentioned above.

Motor mazda

Mazda Develops Improved Four Cylinder Engines

by Mazda in the News on October 14, 2009

Automakers are focusing on future powertrains for major reasons. First, consumers are demanding more fuel efficient engines. Secondly, new emissions regulations have placed pressure on automakers to reduce their fleet-wide fuel economy. While some automakers that have truck and SUV heavy lineup are a little more at risk, even Mazda is researching new ways to build fuel efficient gasoline and diesel engines.

Mazda’s goal is to reduce the fuel economy of its lineup globally by the year 2015 according to Alberta Mazda dealers. The earliest result of this push will be a new four cylinder engine that will be introduced in 2011. A redesigned version of the familiar 2.0-liter four cylinder engine and an all-new six-speed automatic transmission will help increase fuel mileage in city driving from 22 mpg to 32 mpg. A used Mazda dealer Calgary believes the strategy was to make such technology widely available, and not to limit it to just a few vehicles within Mazda’s global lineup. While no specific vehicle has been identified to receive this new engine, sources say it could be applied to numerous existing vehicles without significant modification.

Two vehicles that will likely receive new fuel efficient engines first are the Mazda MX-5 roadster and the Mazda5 MPV. Not only will these engines be available fleet wide by 2015, but Mazda Calgary suggests they will give consumers added fuel efficiency without the added costs usually associated with regenerative braking and hybrid powertrains.

Rotary engines, such as the one found on the Mazda RX-7, are also continually being developed by the automaker. The next generation rotary engine is said to have more than 30 percent improved fuel economy, while also featuring reduced weight over the existing engine.http://www.mazdainthenews.com

How a Eaton G80 locker works

Eaton G80 locking differential. Click image to enlarge |

By Jim Kerr; photos by Chris Chase

Drive axle, rear axle, differential: they are all terms we use when describing the unit that directs the engine’s power from the transmission to the tires. Differential may be the best term to use, because the drive wheels have to turn at different speeds when the vehicle goes around a corner. The differential allows this. It also splits the torque to the drive wheels, which is great when the tires are on good traction surfaces, but put one wheel on ice or loose dirt and you can easily become stuck. That’s where Eaton’s locking differential comes in useful.

Locking differentials lock both wheels together when additional traction is needed. This is usually done on rear axles only, because locking the front axle makes it very difficult to steer. Mercedes G500’s have offered an electric locking front axle, and combined with the locking rear axle, it is perfect for getting the vehicle over fallen logs and out of deep mud holes, but switch it off if you want to turn.

Dana and Eaton are two manufacturers of locking axles. Both have been around for decades. You can find Dana locking axles in a variety of larger trucks and delivery vans. They are designed for heavy-duty use and they have been used in everything from Canada Post delivery vans to one-ton Dodge trucks. Eaton has been making locking axles for both light duty and heavy-duty vehicles since 1973, and you only find them in GM vehicles.

Eaton recently demonstrated the advantages of a locking differential in a rear-wheel drive pickup over even the best four-wheel drive system and four wheel traction control. The vehicles were positioned with one wheel on dry pavement and the other rear wheel on a set of rollers to simulate a start with one wheel on ice. An object placed in front of one front wheel simulated driving up a curb or out of a rut. Then the driver attempted to drive each vehicle away.

Without a locking axle, the wheel on the rollers would spin but the vehicle wouldn’t move. Even with traction control, which brakes the spinning wheel to cause torque to transfer to the other side, there wasn’t enough traction to cause the vehicle to climb over the obstacle.

http://www.canadiandriver.com

Next Generation Rotary Engine

Mazda Planning Direct Injection for Next Generation Rotary Engine

by George DelozierRotary engines are almost always associated with the name Mazda. For their small size, they can produce quite a bit of power, but at the expense of fuel economy and tailpipe emissions. Mazda, most likely in an effort to reduce the latter two, has been granted a patent for a newly designed rotary engine.

Among the minor changes to the famed rotary engine is the inclusion of direct injection and additional spacing between the pair of spark plugs. Although small, these changes could return some respectable gains in both the power and fuel economy department.

From the diagram, it also appears that the displacement will also be raised slightly above the previous 1.3 liters. Alongside the direct injection and more efficiently placed spark points, this new design could see a drastic drop in emissions as compared to the current examples.

The change in spacing would also allow Mazda engineers to alter the interior of the combustion chambers and improve airflow characteristics.

Mazda has yet to confirm or deny any plans for the future of their Renesis engine, but this would be a big step in the right direction if Mazda plans on continuing the rotary's legacy.